automotive heat exchangers

With our product range, as well as material options, we are able to cover most of the heat exchangers found in the automotive industry. Our products include straight fin and corrugated fin radiators as well as seamless tube oil-coolers and intercoolers both in copper and steel. On the other hand, and making sure to adapt with the market, we are able to build fully aluminium radiators, oil-coolers and intercoolers using extruded tubes. With all our automotive heat exchangers we utilise the flux brazing technique for core manufacturing. What sets us apart is that we are the only manufacturer of customer specific aluminium heat exchangers in Africa and capable of producing single itemed units, making no job too small or too big for us.

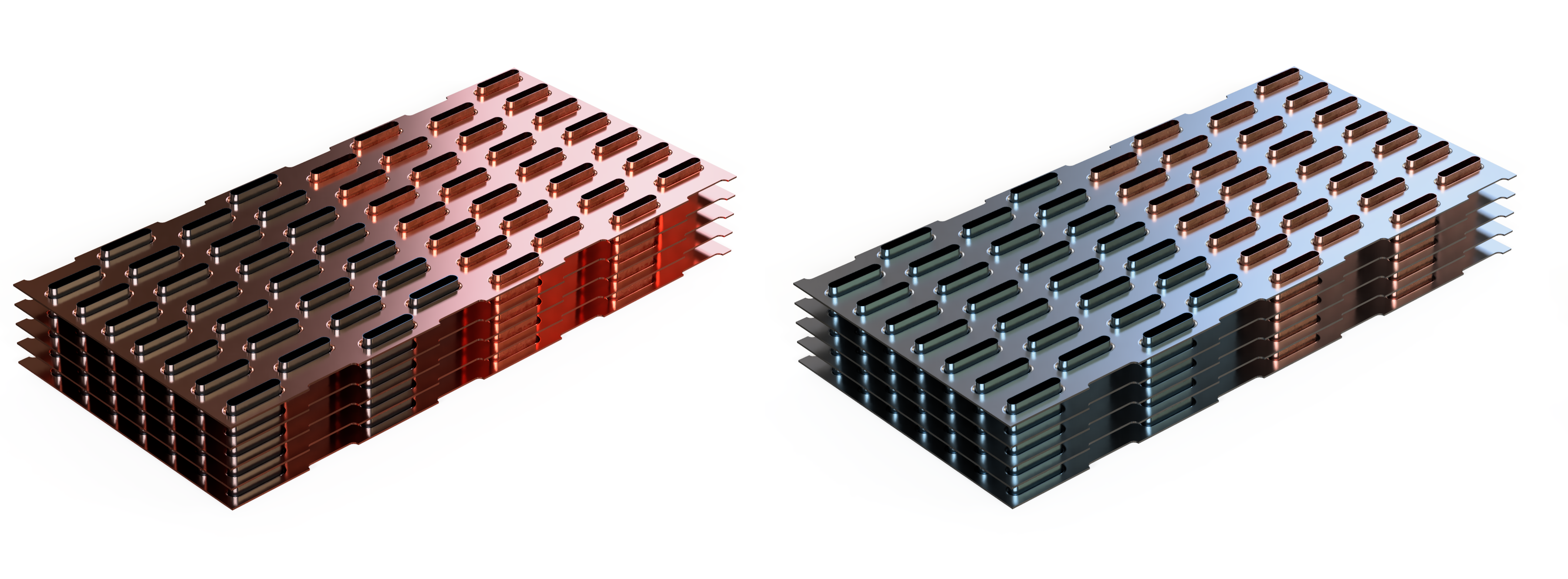

Straight Fin Radiators: Copper & Steel

Copper & Steel (Straight Tube : SG & SGS)

- SG - 2 row up to 8 tube rows (37 to 151 mm core thickness)

- SGS - 3 row up to 8 tube rows (57 to 151 mm core thickness)

- Fin Density: 16 to 45 f/dm

- 10 mm Tube Pitch

- 13.6 x 2.6 mm Tube

- SG - 0.07mm Fin Thickness

- SGS - 0.1mm Fin Thickness

Steel (Angle Tube : AT)

- 3 row up to 8 rows (57 to 151 mm core thickness)

- Fin Density: 16 to 33 f/dm

- 15.88 mm Tube Pitch

- 13.2 x 2.6 mm Tube

- 0.21mm Fin Thickness

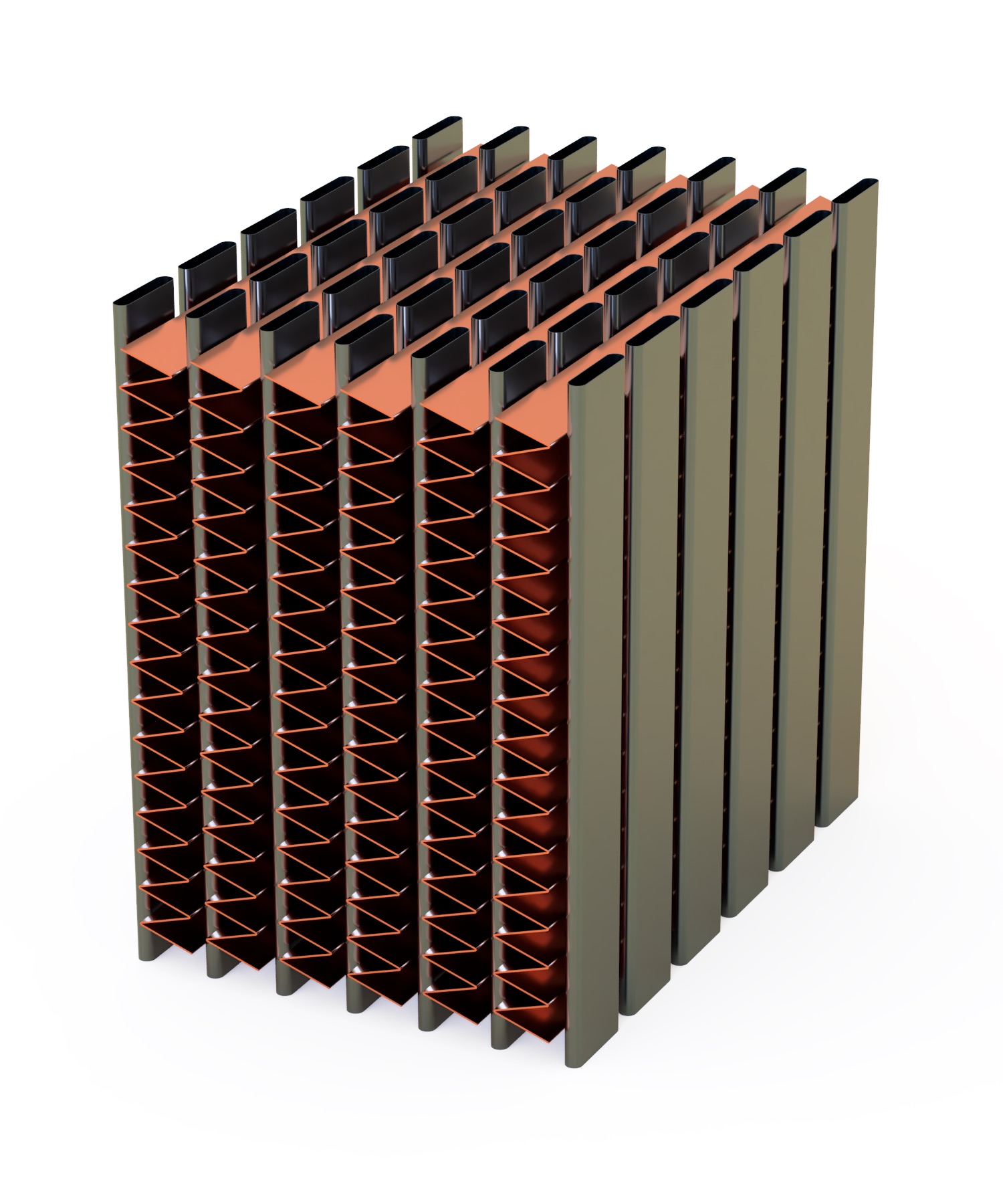

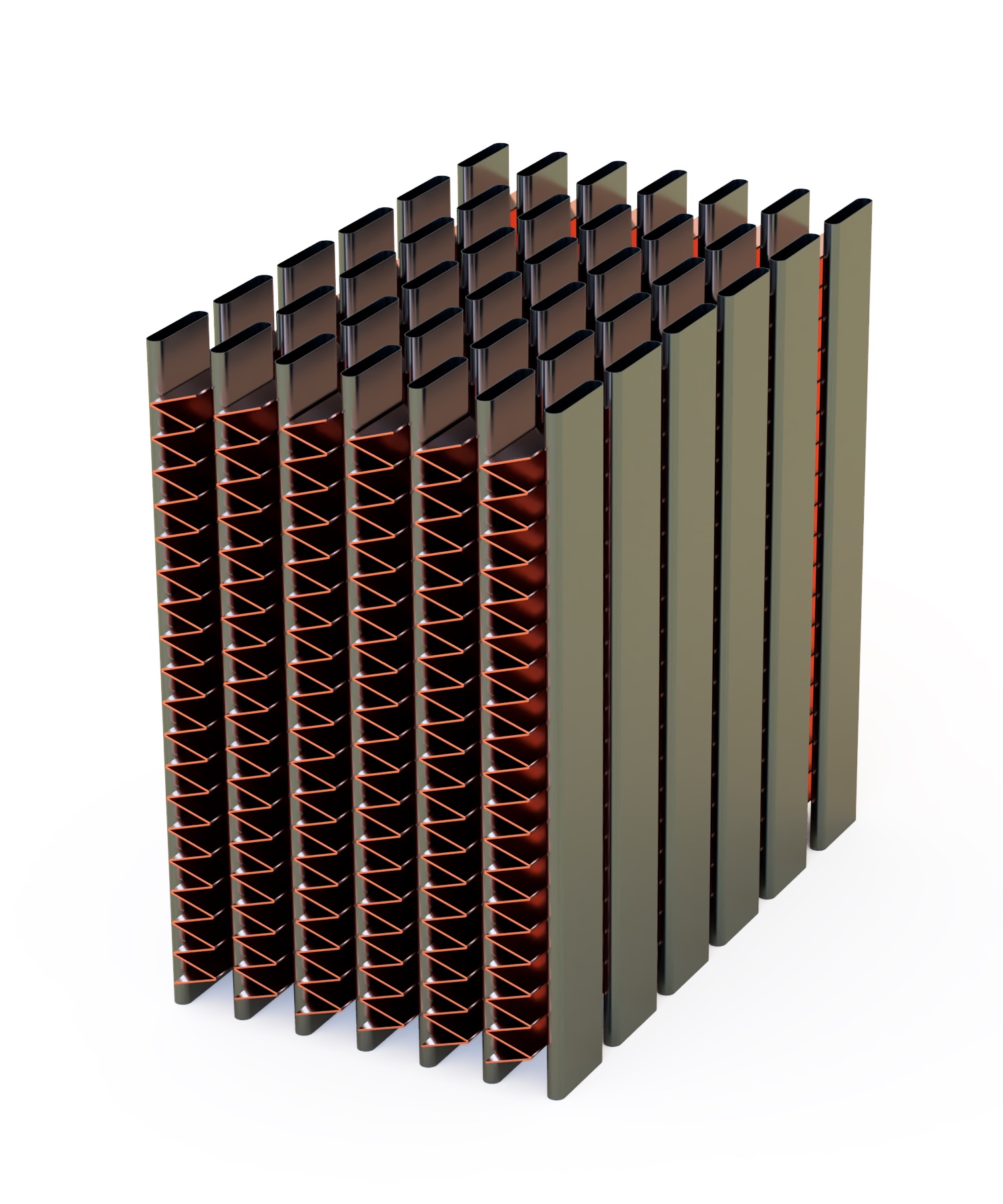

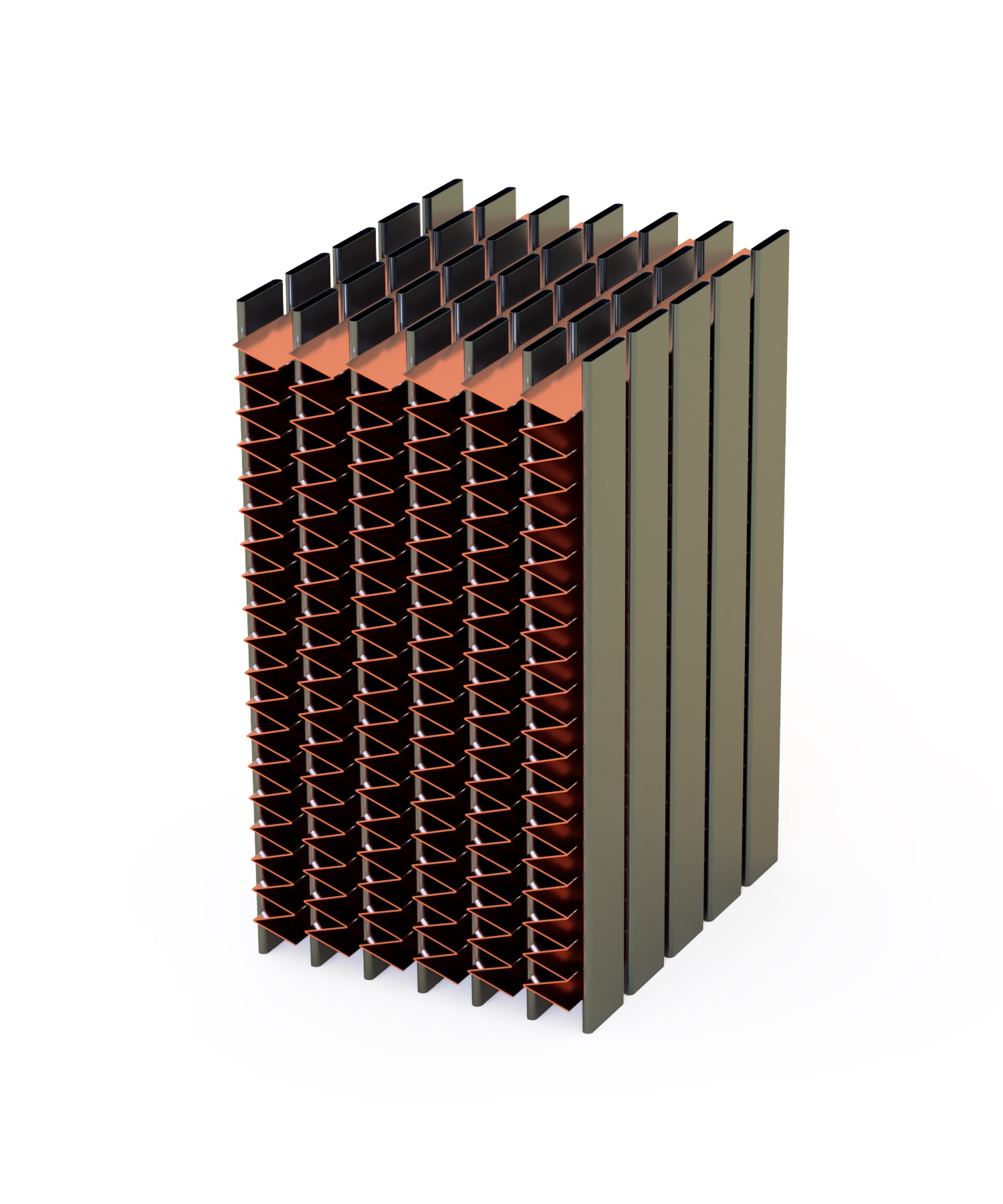

Corrugated Fin Radiators: Copper

CN (Packed Type)

- 1 row up to 6 tube rows

(16 mm up to 100 mm core thickness) - Fin Density: 45 to 60 f/dm

- 11.5 mm Tube Pitch

- 13.6 x 2.6 mm Tube

- 0.04mm Fin Thickness

CL (Packed Type)

- 2 row up to 6 tube rows

(32 mm up to 100 mm core thickness) - Fin Density: 45 to 80 f/dm

- 10 mm Tube Pitch

- 13.6 x 2.6 mm Tube

- 0.04mm Fin Thickness

NG (Packed Type)

- 2 row up to 5 rows

(27 mm up to 69 mm) - Fin Density: 45 to 80 f/dm

- 8.5 mm Tube Pitch

- 11 x 1.5 mm Tube

- 0.04mm Fin Thickness

Corrugated Fin Radiators: Aluminium

Corrugated Fin Radiators: Aluminium

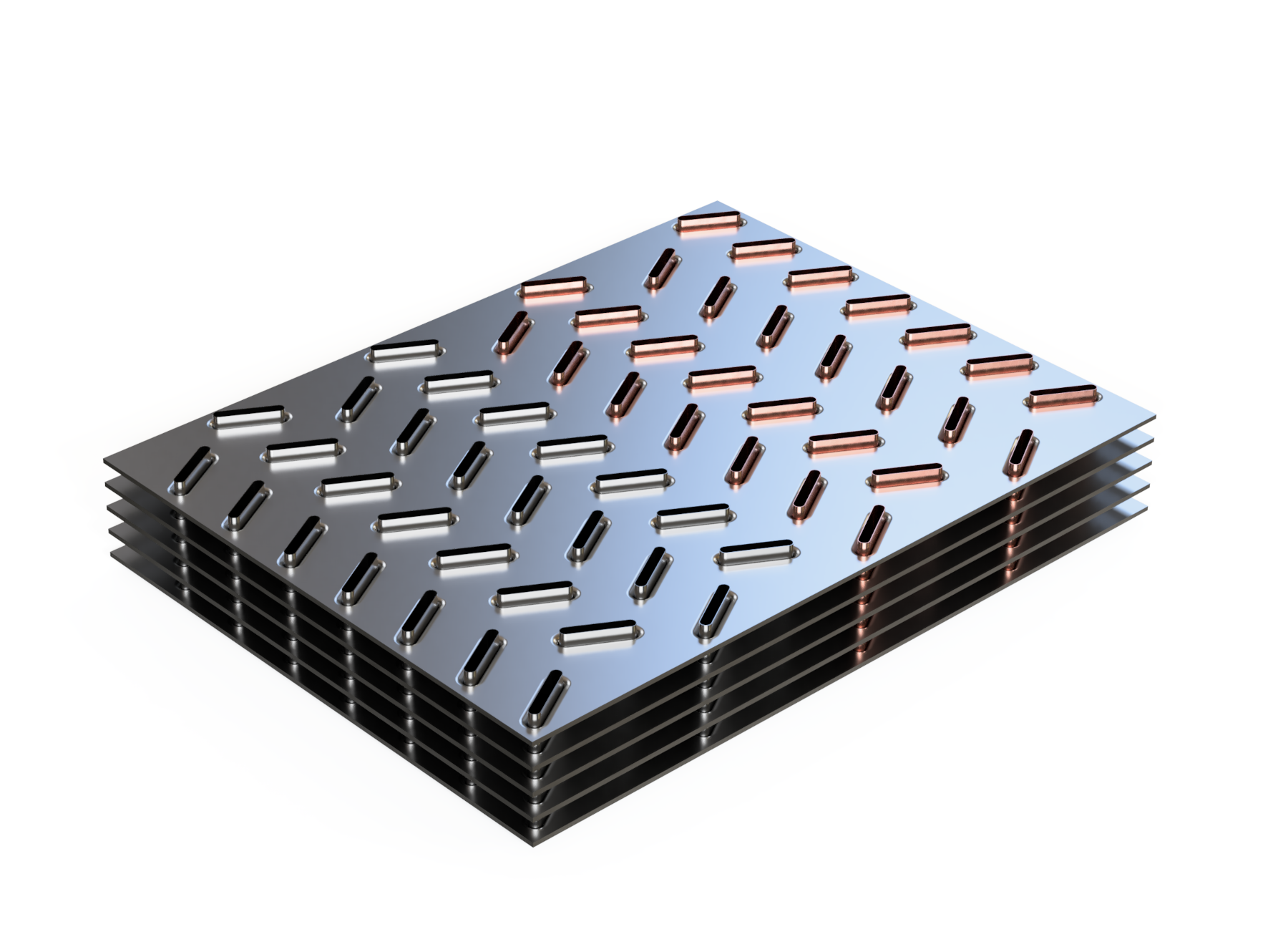

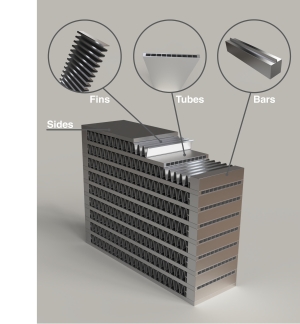

Tube & Bar Heat Exchanger

The core is constructed by layering the individual components as illustrated; before everything is brazed to form a single core. Easily confused with a plate and bar heat exchanger. The difference being, that the tube is a single extruded tube not like a plate and bar that is built up with individual components that make up the tube.

Our extruded tubes are thicker than that of the plate and bar heat exchangers and the single extruded tubes have fewer interfaces that may leak. This all leads to greater durability; and our aim to build the strongest possible aluminium heat exchanger.